Summary

This article mainly explores the application principle and substitution of DC link film capacitors and aluminum electrolytic capacitors in inverters, analyzes the performance characteristics, working principles and specific roles of the two capacitors in inverter, focuses on comparing the impact of the ESL and ESR of DC link capacitors on system performance, and elaborates on the substitution calculation and key technical points of the two capacitors in practical applications, providing valuable reference for the design of power electronic systems.

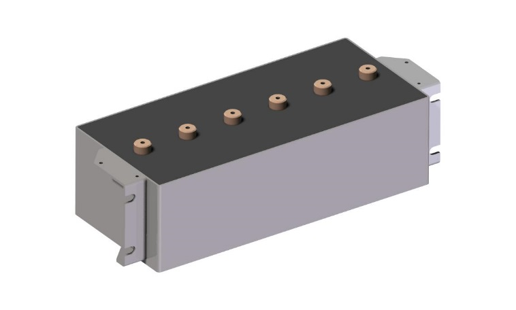

1.DC link capacitors are key components for the stability of the DC bus voltage of inverters

DC link capacitors have the important functions of stabilizing the DC bus voltage, absorbing high-frequency ripple current and providing instantaneous energy buffering in inverters. As the core passive component of the DC side of the inverter, the performance of the DC link capacitor directly affects the reliability and efficiency of the entire inverter system. Compared with traditional aluminum electrolytic capacitors, DC link capacitors made of film material have lower ESL and ESR, and can more effectively suppress voltage fluctuations. The ESL of the DC link capacitor determines its high-frequency response characteristics, while the ESR of the DC link capacitor directly affects the energy loss and temperature rise characteristics. During the operation of the inverter, the DC link capacitor needs to withstand the pulse current generated by the high-frequency switching device, which requires the DC link capacitor to have excellent frequency characteristics and stability.

2.The application of aluminum electrolytic capacitors in inverters has inherent limitations

Aluminum electrolytic capacitors have long dominated the application of inverter DC link due to their high volume specific capacitance and low cost. However, the ESL and ESR of aluminum electrolytic capacitors are significantly higher than those of DC link film capacitors, which leads to a sharp decline in their performance under high temperature and high frequency conditions. Especially in modern high-frequency inverters, the electrolyte drying problem of aluminum electrolytic capacitors has become a bottleneck for the life of the system. In contrast, the DC link capacitor uses metallized film technology, there is no problem of electrolyte evaporation, and the ESL of the DC link capacitor can be controlled below 10nH, and the ESR of the DC link capacitor is only 1/5 to 1/10 of that of the aluminum electrolytic capacitor. These characteristics make DC link capacitors show obvious advantages in high power density inverters.

3.The equivalent parameters of DC link capacitors have a decisive influence on system performance

The ESL and ESR of DC link capacitors are key indicators for evaluating their performance, which directly affect the efficiency and reliability of the inverter. The ESL of DC link capacitors is closely related to the internal structure design. Low ESL means better high-frequency current absorption capacity, which can effectively suppress the voltage spikes caused by IGBT switching. Experimental data show that reducing the ESL of DC link capacitors from 50nH to 15nH can reduce voltage ripple by more than 40%. At the same time, the ESR of the DC link capacitor enhance the self-heating effect of the capacitor. DC link capacitors with low ESR can significantly reduce power loss and improve system efficiency. It is also worth noting that the equivalent parameters of DC link capacitors have excellent temperature stability, with a change rate of less than 5% in the range of -40℃ to +105℃, which is much better than aluminum electrolytic capacitors.

4.Comprehensive consideration the replacement of film and aluminum electrolytic capacitors in inverters

The replacement of DC link film capacitors and aluminum electrolytic capacitors is not a simple one-to-one replacement, and a comprehensive evaluation system needs to be established. In the aspect of capacity replacement, due to the lower ESR of DC link capacitors, the capacity can usually be reduced by a ratio of 1:0.7-0.9. In high-frequency applications, the ESL advantage of DC link capacitors must also be considered, and the replacement capacity can be further reduced. In specific calculations, the voltage ripple requirement of ΔV=(I_pp×ESR)+(L×di/dt) should be met, among which the ESR and ESL of DC link capacitors are significantly better than those of aluminum electrolytic capacitors. In the aspect of working life assessment, under the same working conditions, the service life of DC link capacitors can reach 3-5 times that of aluminum electrolytic capacitors. Cost analysis needs to consider the full life cycle cost. Although the initial cost of DC link capacitors is higher, the maintenance cost and failure are greatly reduced. Actual replacement cases show that after using DC link capacitors, the size of the inverter can be reduced by 30% and the working efficiency can be increased by 1-2 percentage points.

5.DC link capacitors have irreplaceable advantages in high power density inverters

As inverters develop towards high frequency and miniaturization, the technical advantages of DC link capacitors are becoming more and more prominent. In high switching frequency (>20kHz) applications, the ESL characteristics of DC link capacitors enable them to effectively suppress high-frequency harmonics, while aluminum electrolytic capacitors deteriorate due to excessive ESL. In high temperature environments (>85℃), the stability of DC link capacitors is far better than that of aluminum electrolytic capacitors, and they are particularly suitable for harsh working conditions such as wind power and photovoltaics. In addition, the modular design of DC link capacitors facilitates low inductance layout, and the ESR of DC link capacitors can be further reduced through multiple parallel connections. Test data shows that the peak efficiency of inverters using customized DC link capacitor solutions can reach 98.5%,These characteristics of DC link capacitors make them the first choice for high-power and high-reliability inverters.

6.The selection and application of DC link capacitors must follow the principle of systematic design

The reasonable application of DC link capacitors needs to be based on system-level optimization design. First, the capacity requirement of the DC link capacitor should be determined according to the power level and switching frequency of the inverter, and the influence of the ESL and ESR of the DC link capacitor on the system should be considered. The layout should adopt a low-inductance design to minimize the distance between the DC link capacitor and the power module. For high-power applications, DC link capacitors can be connected in parallel to reduce the overall ESR and improve reliability. In the aspect of thermal management, although the temperature rise of the DC link capacitor is low, good heat dissipation conditions must still be considered. In actual projects, details such as the installation torque and wiring method of the DC link capacitor will affect its equivalent parameters and must be operated strictly in accordance with the specifications. The monitoring system should also pay attention to the working status of the DC link capacitor and promptly warn of abnormal conditions.

Conclusion

DC link film capacitors are gradually replacing traditional aluminum electrolytic capacitors in modern inverters with their advantages of ESL, ESR and long life. Through scientific substitution calculation and systematic design, the use of DC link capacitors can significantly improve the power density, efficiency and reliability of the inverter. Although the initial cost is higher, DC link capacitors have obvious economic advantages from the perspective of the full life cycle cost. With the advancement of material technology and manufacturing processes, the performance of DC link capacitors will be further improved, and the scope of application will continue to expand, becoming a standard configuration in the field of inverter DC link. In the future, DC link capacitors will become a development trend, providing key link function for the miniaturization and efficiency of power electronic equipment.