Products

Optimized & Film capacitor Solutions

For All Your Complicated Needs

Our motor running film capacitors are made of selected high-quality materials and precision manufacturing, providing excellent capacitance stability and ultra-low loss. They help the motor to run continuously and smoothly, significantly improve efficiency, reduce temperature rise and energy consumption, and extend the life of the motor. High temperature resistance, long life, safety and reliability, it is an ideal choice to ensure efficient and energy-saving operation of industrial equipment

Optimized & Film capacitor Solutions

For All Your Complicated Needs

Our DC link film capacitors are specially designed for new energy, industrial frequency conversion and other fields. They have ultra-high withstand voltage, ultra-low ESR, and excellent ripple current capability, effectively suppressing voltage fluctuations and ensuring stable and efficient operation of the system. They are resistant to high temperatures, have a long life, are safe and reliable.

Our Innovations

Industry Focused Products!

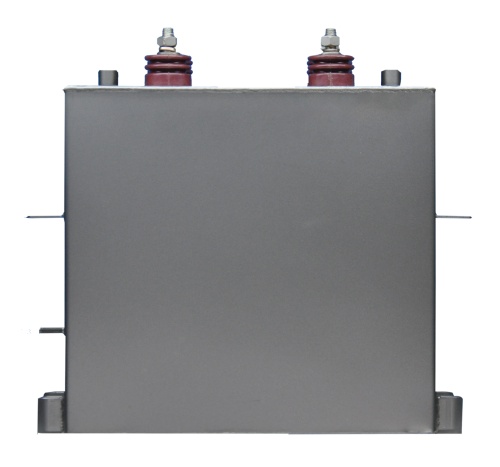

DC Link Capacitor

DC support film capacitors are mainly used in new energy power generation (photovoltaic, wind power), electric vehicles, industrial inverters, rail transit and smart grids, providing promotion and energy storage for DC supports.

AC Motor Capacitor

AC operating film capacitors are mainly used for the continuous operation of single-phase motors (such as fans, water pumps, compressors, etc.), providing phase shifting, maintaining stable operation of the motor, and improving the power factor.

AC Start Capacitor

AC starting film capacitors are mainly used for single-phase motor starting (such as air conditioners, refrigerators, washing machines and other household appliances), providing starting torque and phase shift to ensure smooth start of the motor.

Microwave Capacitor

Microwave film capacitors are mainly used for high-frequency resonance, filtering and energy buffering to ensure stable operation of Microwave, suppress electromagnetic interference (EMI), and improve heating efficiency and system reliability.